最大限度地提升您的 PCB 触摸按钮弹簧体验

在技术进步日新月异的背景下,印刷电路板 (PCB)触摸按钮弹簧已成为一种关键组件,彻底改变了各种设备的用户界面。随着我们深入研究 PCB 触摸按钮弹簧的复杂性,我们揭开了增强用户体验的秘密,并阐明了让我们的理解与众不同的细微差别。

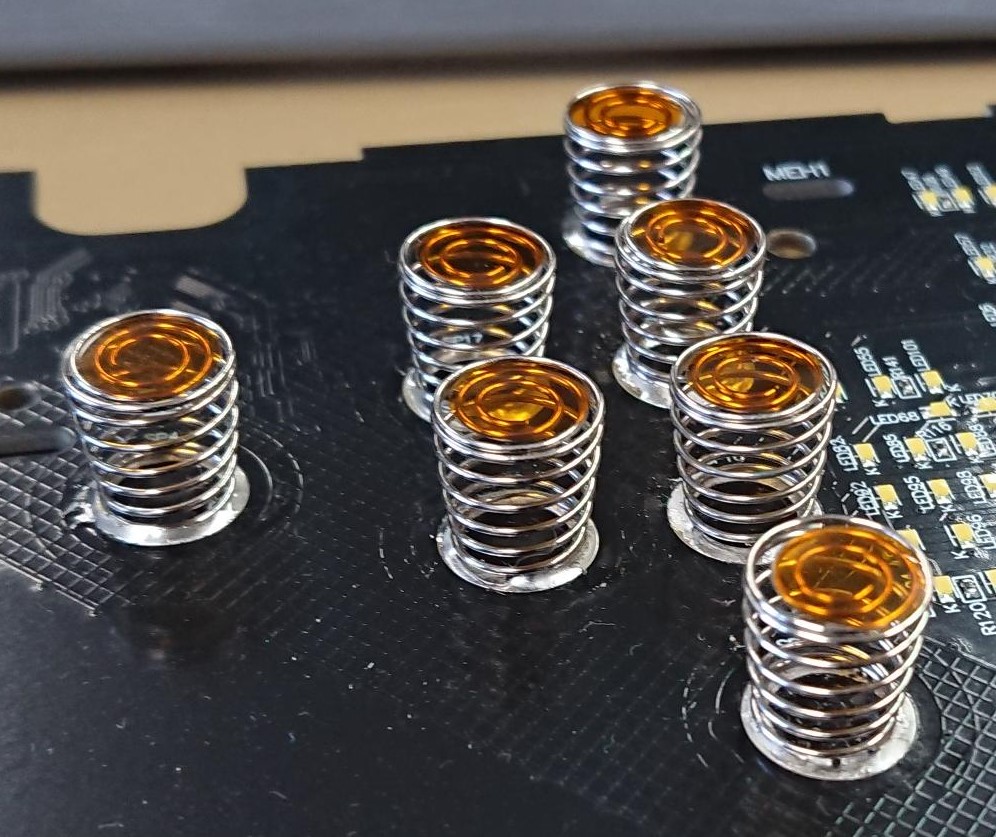

了解 PCB 触摸按钮弹簧

PCB 触摸按钮弹簧有何不同?

PCB 触摸按钮弹簧经常被忽视,但在现代设备界面中却起着至关重要的作用。它们不仅仅是机械部件,更是精密工程的杰作。这些嵌入电子设备中的弹簧可通过触摸感应界面实现无缝交互。其独特之处在于它们能够提供触觉反馈,使用户体验更加直观和引人入胜。

精密工程:PCB触摸按钮弹簧的核心

每个 PCB 触摸按钮弹簧的核心都是精密工程。这些弹簧经过精心制作,以确保最佳的响应性、耐用性和使用寿命。其制造所用的材料经过严格测试,保证在长时间使用中具有可靠且一致的触觉响应。

优化用户交互:让每一次触摸都发挥作用

增强响应能力

PCB 触摸按钮弹簧的响应性是区别于传统界面的关键因素。通过集成尖端技术,制造商可确保每次触摸都能产生快速准确的响应,从而将整体用户体验提升到新的高度。

定制化体验

没有两个用户是相同的,PCB 触摸按钮弹簧承认这种多样性。高级定制选项允许制造商定制这些弹簧的灵敏度,以满足个人喜好和应用要求。无论是轻敲还是用力按压,响应性都可以微调到完美。

寿命和可靠性:揭示工程卓越性

重新定义耐用性

在用户界面领域,耐用性至关重要。PCB 触摸按钮弹簧在设计时充分考虑了使用寿命,经过严格测试,确保经得起时间的考验。其坚固的结构保证了较长的使用寿命,减少了频繁更换的需要,并提高了电子设备的整体可靠性。

环境恢复力

除了日常磨损之外,PCB 触摸按钮弹簧在各种环境条件下都表现出卓越的弹性。从温度变化到湿度水平,这些弹簧都能继续发挥最佳功能,使其成为从消费电子产品到工业控制系统等各种应用的理想选择。

克服挑战:故障排除和维护技巧

解决常见问题

尽管 PCB 触摸按钮弹簧具有出色的工程性能,但偶尔也会遇到问题。了解常见的挑战(例如无响应或反馈不一致)可帮助用户有效地排除故障。清洁界面或调整灵敏度设置等简单措施通常可以解决这些问题,从而确保无缝的用户体验。

定期维护以延长性能

为了最大限度地延长 PCB 触摸按钮弹簧的使用寿命,采用日常维护措施至关重要。定期清洁、检查和校准有助于保持性能,防止潜在问题发生。这种主动方法可确保用户长期继续享受其设备的全部优势。

结论

PCB 触摸按钮弹簧的世界是精密工程、定制、耐用性和弹性的迷人融合。当您探索这些技术奇迹的复杂性时,了解它们的细微差别可以帮助您在选择或排除包含 PCB 触摸按钮弹簧的设备故障时做出明智的决定。